WIt doesn’t matter if you live in the American West, which is rapidly drying, or if you are on the International Space Station for six months, water security is a constant concern. As climate change continues to play havoc on the West’s aquifers, and as humanity pushes further into the solar system, the potable supply challenges we face today will only grow. , some of NASA’s cutting-edge in-orbit water recycling research is coming back down to Earth.

The Earth

California is an example of this. from the state’s homes and businesses, storm drain and roof-connected runoff, makes its way through more than 100,000 miles of sewer lines where it — barring — eventually ends up at one of the state’s 900 wastewater treatment plants. How that water is processed depends on whether it’s destined for human consumption or non-potable uses like agricultural irrigation, wetland enhancement and groundwater replenishment.

Reclaiming potable wastewater requires a multi-step strategy. Large solids are first strained from incoming fluids using mechanical screens at the treatment plant’s headworks. From there, the wastewater flows into a settling tank where most of the remaining solids are removed — sludged off to anaerobic digesters after sinking to the bottom of the pool. The water then goes to secondary processing, where it is aerated using nitrogen-fixing bacteria, before being pushed into another clarification, or settling, tank. Finally it’s filtered through a tertiary cleaning stage of cationic polymer filters where any remaining solids are removed. In 2035 Both Atlanta, Georgia and Aurora, Colorado have already started to increase their drinking water supply with potable reuse.

“There are additional benefits beyond a secure water supply. If you’re not relying on importing water, that means there’s more water for ecosystems in northern California or Colorado,” Stanford professor William Mitch, said in . “You’re cleaning up the wastewater, and therefore you’re not discharging wastewater and potential contaminants to California’s beaches.”

California’s wastewater treatment plants face many challenges. Notables include an aging infrastructure, contamination from untreated pharmaceuticals and pesticide runsoff, population demands as well as reduced flows caused by climate change-induced drought. Their ability to provide pristine water is superior to that of nature.

“We expected that potable reuse waters would be cleaner, in some cases, than conventional drinking water due to the fact that much more extensive treatment is conducted for them,” Mitch argued in an October study in . “But we were surprised that in some cases the quality of the reuse water, particularly the reverse-osmosis-treated waters, was comparable to groundwater, which is traditionally considered the highest quality water.”

Recycled solids are also treated with heavy amounts of wastewater. The waste from the first stage goes to landfills. The biological solids from the second and the third stages go to anaerobic chambers to decompose. It can be used for electric production or converted to fertilizer nitrogen-rich for agricultural use.

New York, for instance. There are more than 1,200 statewide wastewater treatment plant (WWTPs) in the state. According to a report by the 2021 Commission, less than 10% of plants (116 in particular) use the sludge to make biogas. , and is “mainly utilized to fuel the facilities and for the combined heat and power generation of the WWTPs.”

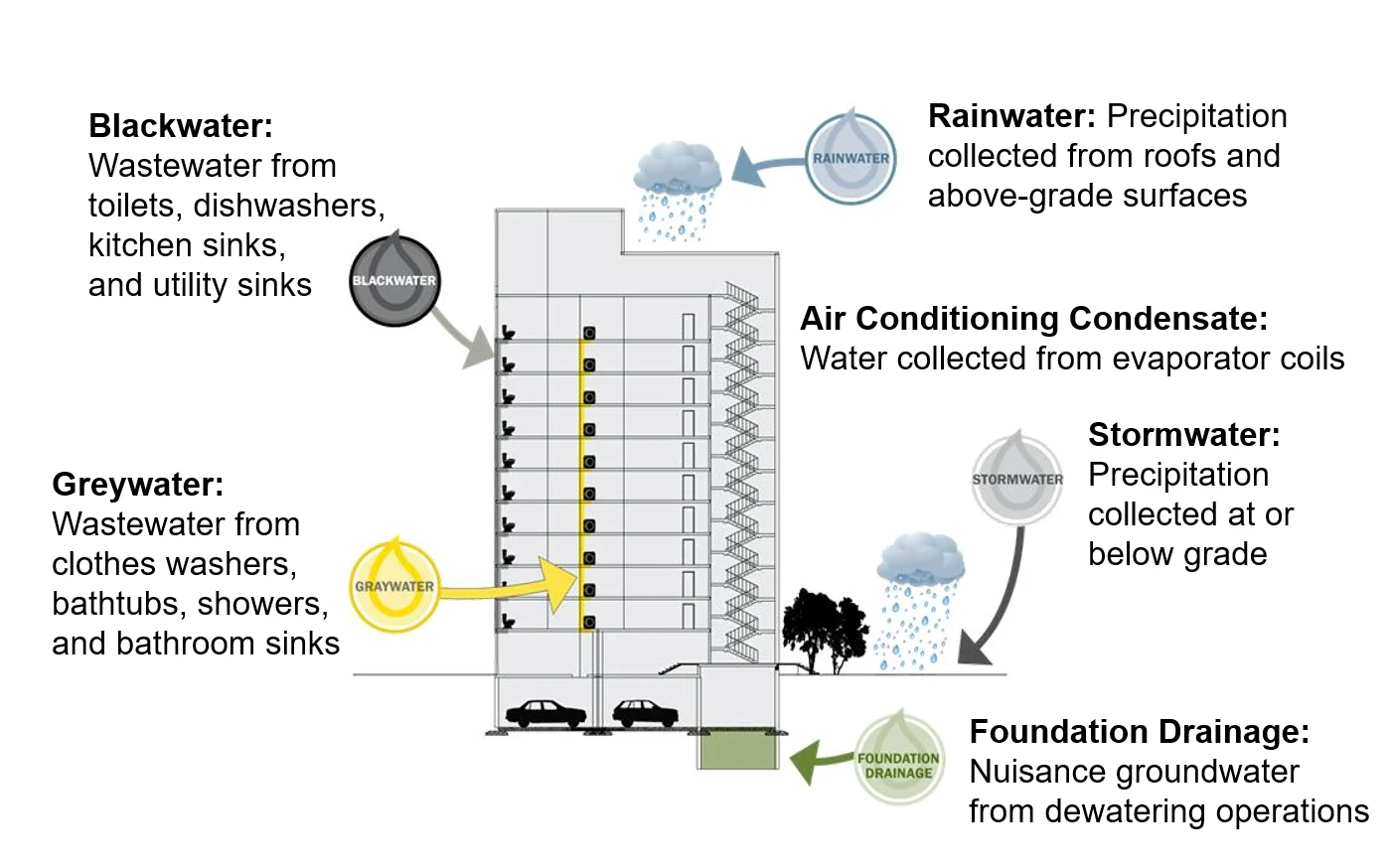

Non-potable waters can be treated further and in some cases even more efficiently. . Wastewater, rainwater, and can After being taken and treated in an, you can water the lobby plants or flush the toilets. (ONWS).

EPA

“Increasing pressures on water resources have led to greater water scarcity and a growing demand for alternative water sources,” the . “Onsite non-potable water reuse is one solution that can help communities reclaim, recycle, and then reuse water for non-drinking water purposes.”

Orbit

Because the station is a closed loop system, astronauts are restricted in how much water they can use. Also because SpaceX charges $2,500 per pound of cargo (after the first 440 pounds, for which it charges $1.1 million) to send into orbit on one of its rockets — and liquid water is heavy.

ESA

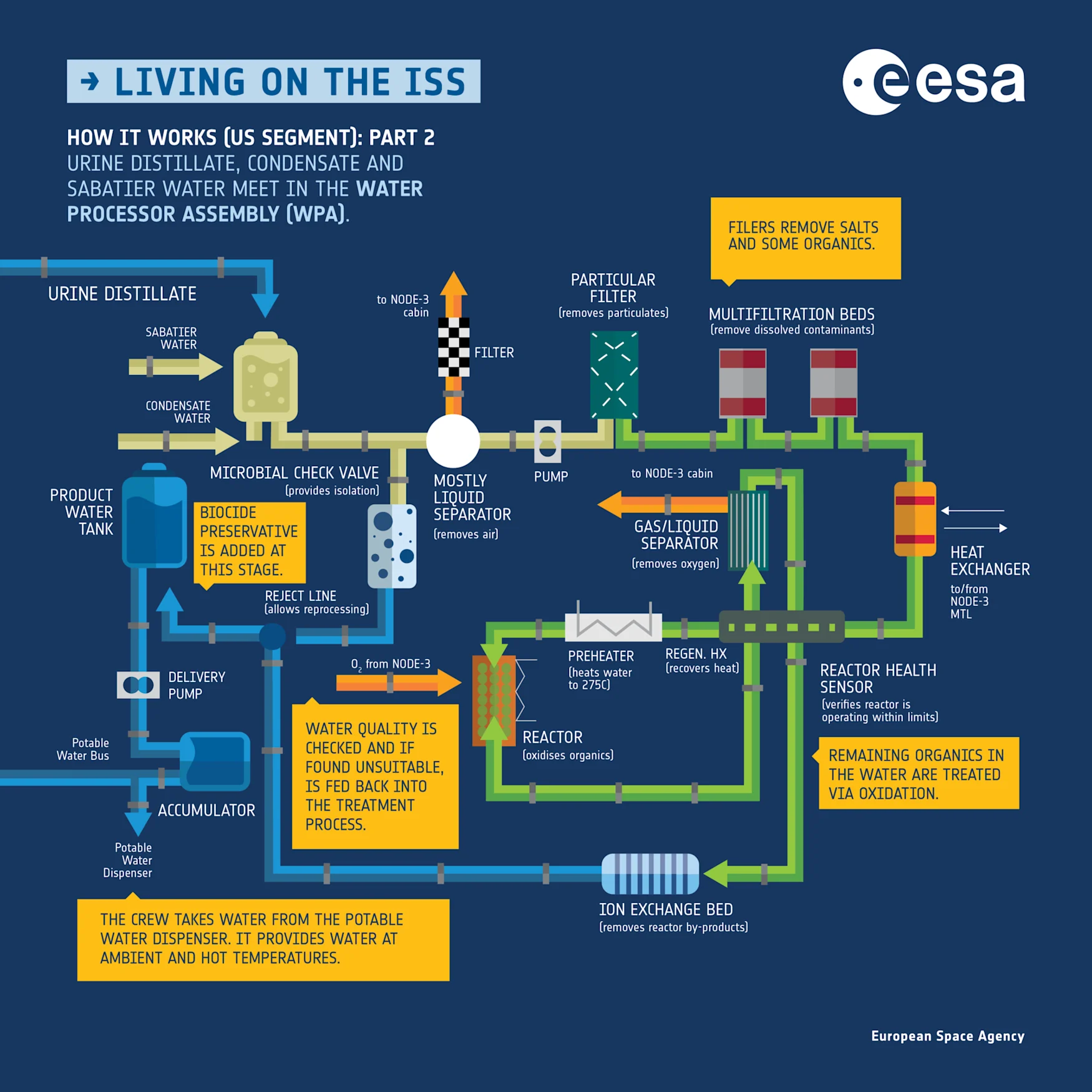

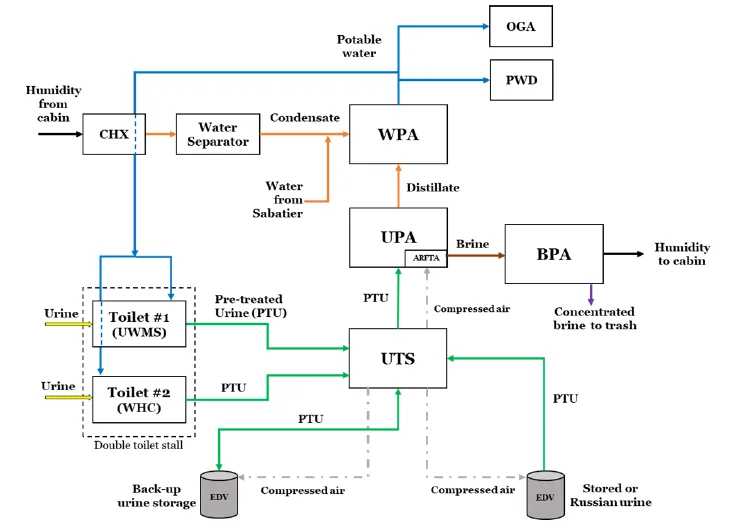

While the ISS does get the occasional shipment of water in the form of 90-pound duffle bag-shaped Contingency Water Containers to replace what’s invariably lost to space, its inhabitants rely on the complicated web of levers and tubes you see above and below to reclaim every dram of moisture possible and process it into potability. The station’s Water Processing Assembly can produce up to 36 gallons of drinkable water every day from the crew’s sweat, breath and urine. When it was installed in 2008, the station’s water delivery needs . It works in conjunction with the Urine Processor Assembly (UPA), Oxygen Generation Assembly (OGA), Sabatier reactor (which recombines free oxygen and hydrogen split by the OGA back into water) and Regenerative Environmental Control and Life Support Systems (ECLSS) systems to maintain the station’s “” and . The Russian segment of the ISS’s Cosmonauts rely on a separate filtration unit that collects only shower runoff and condensation. They therefore need more water to maintain their tanks.

ESA

In 2017, NASA upgraded the WPA with a new reverse-osmosis filter in order to, “reduce the resupply mass of the WPA Multi-filtration Bed and improved catalyst for the WPA Catalytic Reactor to reduce the operational temperature and pressure,” the agency announced that year. “Though the WRS [water recovery system]Since operations began in November 2008 and have performed well, many modifications have been made to the system to improve its performance. These modifications aim to reduce resupply and improve overall system reliability, which is beneficial for the ongoing ISS mission as well as for future NASA manned missions.”

In 2021, the Brine Processor Assembly was upgraded. This filter removes more salt from astronaut urine in order to make more reclaimed waters than its predecessor. We still have a lot to do before we can secure transport crews into interplanetary space. NASA points out that although the WPA delivered in 2008 was initially rated to recover 85 per cent of the water from crew urine, its performance has improved to 87 per cent.

NASA

“To leave low-Earth orbit and enable long-duration exploration far from Earth, we need to close the water loop,” Caitlin Meyer, deputy project manager for Advanced Exploration Systems Life Support Systems at NASA’s Johnson Space Center in Houston, added. “Current urine water recovery systems utilize distillation, which produces a brine. The [BPA] will accept that water-containing effluent and extract the remaining water.”

When the post-processed urine is then mixed with reclaimed condensation and runs through the WPA again, “our overall water recovery is about 93.5 percent,” Layne Carter, International Space Station Water Subsystem Manager at Marshall, . NASA believes that it will need a reclamation rate at least 98 per cent to safely reach Mars.

But even if the ISS’s current state-of-the-art recycling technology isn’t quite enough to get us to Mars, it’s already making an impact planetside. For example, in the early 2000’s the Argonide company developed a “NanoCeram” nanofiber water filtration system with NASA small business funding support. The filter removes virtually all contaminants using positively charged microscopic Alumina fibers. This allows for a high flow rate and eventually spawning. .

“The shower starts with less than a gallon of water and circulates it at a rate of three to four gallons per minute, more flow than most conventional showers provide,” . “The system checks water quality 20 times per second, and the most highly polluted water, such as shampoo rinse, is jettisoned and replaced. The rest goes through the NanoCeram filter and then is bombarded with ultraviolet light before being recirculated.” According to the Swedish Institute for Communicable Disease Control, the resulting water is cleaner than tap.

Engadget has chosen all products to recommend. We are not affiliated with our parent company. Some stories may contain affiliate links. Affiliate commissions may be earned if you make a purchase through any of the links. All prices correct as of the date of publication.