The new method of making wiring for flexible, bendy electronics by zapping liquid metal dropslets using ultrasound is a novel way to do it.

The techniqueThe Nov. 11 article describes the benefits of. ScienceResearchers who are developing circuitry to attach medical sensors to the skin will now have a new tool in their arsenal. wearable electronicsOther applications in which rigid circuit electronic are less than idealSN: 6/1/18).

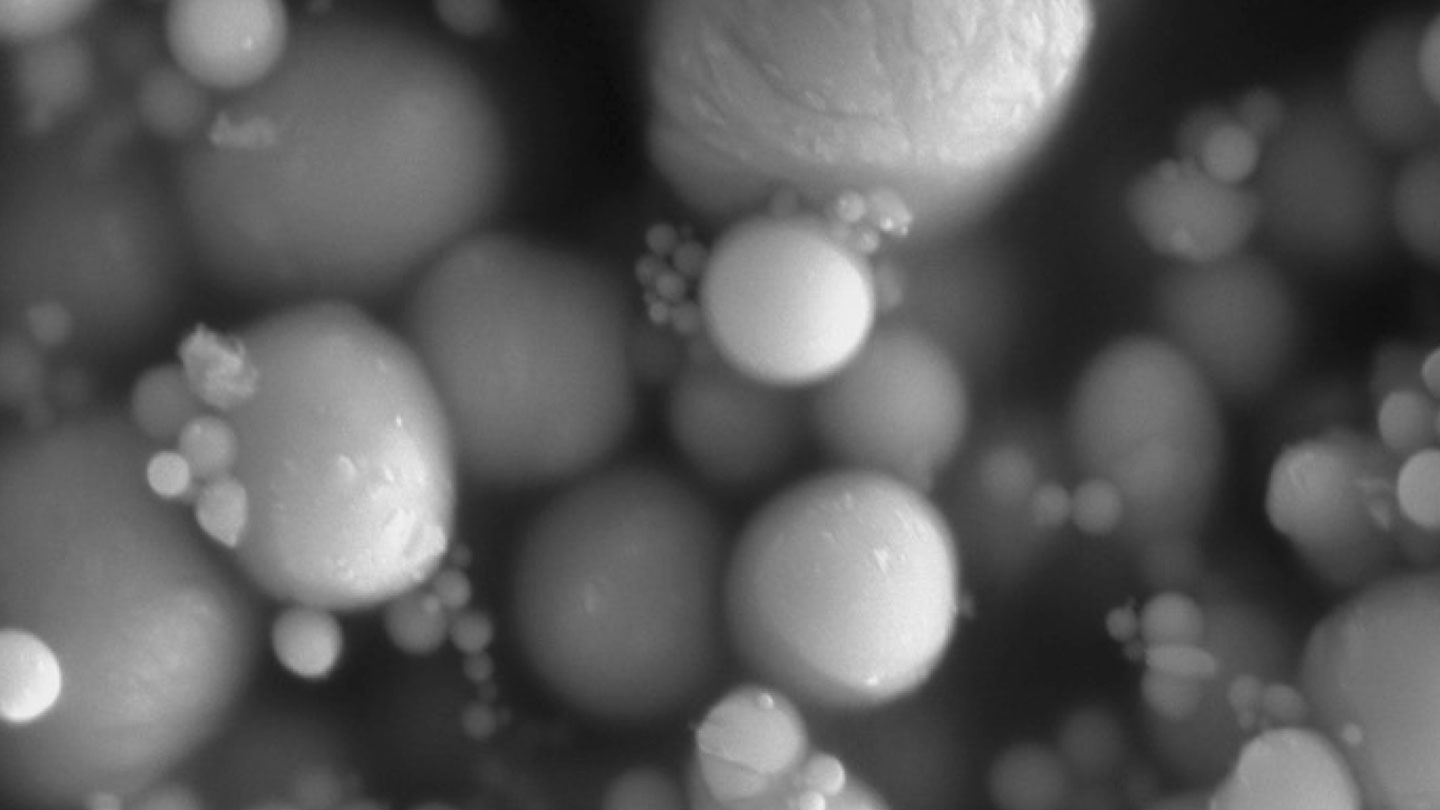

The researchers started by drawing lines on stretchy plastic sheets with microscopic droplets of an alloy of indium and gallium. The metal alloy is liquid at temperatures above about 16° Celsius.

The liquid metal is very electrically conductive but the droplets oxidize quickly. This covers them with a thin layer that acts as an insulator. These layers are charged with static charges, which push the drops apart and render them ineligible for connecting microchips, LEDs, or other electronic components.

Researchers hit the microspheres using high-frequency sound waves to make the liquid metal particles even smaller. These tiny spheres bridge gaps between larger ones. This close contact allows electrons through oxide layers to pass through, allowing droplets to carry electricity.

If the plastic used to print the drops is bent or stretched, the larger balls can become deformed. The smaller ones, however, act as rigid particles and shift around to maintain contact.

The researchers showed their conductors in action by connecting electronics to a stretchy pattern made of LEDs. This display displayed the initials for the Dynamic Material Design Laboratory. The researchers also constructed a sensor using the conductors. monitor blood through a person’s skin (SN: 2/17/18).

Flexible electronics applications aren’t new, says materials scientist Jiheong Kang of the Korea Advanced Institute of Science and Technology in Daejeon, South Korea. He says that the new design has some advantages over previous designs that depend on liquid metal channels that could leak if damaged circuitry. Kang and his colleagues created conductors made of liquid metal that stay in the plastic. The plastic is not torn and the liquid metal remains trapped within the tiny spheres.

Liquid metal wires have been used as conductors in stretchy electronics for a long time, according to Carmel Majidi (a Carnegie Mellon University researcher in mechanical engineering who was not part of the new study). Using ultrasound introduces a “novel approach to achieving that conductivity.” Other groups have managed that feat by heating circuits, exposing them to lasers, squishing them or vibrating the circuits to get droplets to connect to each other, he says.

Majidi isn’t convinced that the ultrasound approach is a game changer for flexible circuits. But he says that it’s high time the subject is appearing in a leading journal like Science. “I’m personally really excited to see the field overall, and this particular type of material architecture, is now gaining this visibility.”